Our injection molding process delivers top-quality injection molds for your custom injection molded parts. Receive precise and exceptional custom injection molds to produce premium plastic parts efficiently and affordably for your injection molding projects.

Injection mold tooling plays a critical role in the precision and quality of the final product produced through injection molding. The careful design and manufacturing of the mold ensure that each component of the finished product is consistent and free of defects. Without well-made molds, the injection molding process would not be as efficient or reliable, leading to issues with product quality and production costs. In conclusion, injection mold tooling is essential in the manufacturing of plastic products and is a key factor in the success of the injection molding process.

F&Q TECH offers all types of injection molds according to your requirements, from prototype molds to production and export molds, ensuring you a reliable and high-quality service.

● By Purposes

|

Classification |

Advantage |

|

Injection Molding Prototypes |

High-quality prototype molds could help you easily receive design feedback and validation. F&Q TECH can quickly create these molds in a matter of days, allowing you to produce small batches of plastic molded parts for functional testing and market validation. |

|

Production Tooling |

For the production of plastic parts in large quantities, we produce high-quality production molds. Our industrial tooling is capable of creating millions of parts thanks to the use of strong, long-lasting tool steel. Depending on your particular needs, we can change the materials and building techniques. |

● By Types

|

Classification |

Advantage |

|

Single Cavity Mold |

With premium single-cavity injection molds, you can produce plastic parts in low volumes effectively. These affordable choices for mold tooling allow you more control over the production of plastic. |

|

Multi Cavity Mold |

Using high-quality multi-cavity molds, produce numerous plastic molded parts quickly. Our multi-cavity injection molds guarantee more efficient cycle times while providing lower unit part costs. Higher productivity enables you to produce large numbers of parts per cycle. |

|

Stack Mold |

Incorporating innovative laminated molds could enhance your injection molding process and reduce overall part costs. F&Q TECH increases your molding efficiency and throughput and even creates multi-component assemblies in a single pass. Choose from molds with the same or different numbers of cavities per parting face to best suit your needs |

|

2K Injection Mold |

A cost-effective approach for custom injection molding that uses two different plastic materials. For a product to seamlessly combine soft and hard plastics, we provide 2K injection mold tooling. Costs can be reduced by making products to order and integrating many assembly procedures into a single molding process. |

Advantages of Injection Molding Tooling

Using molds in the production process greatly enhances the stability of material application, decreases waste, and guarantees top-notch product quality. A wide range of industries have experienced significant advantages from utilizing molds, particularly injection molds.

Our Injection Mold Tooling Processes

F&Q TECH specializes in creating custom molds tailored to your specific needs. Our team of expert engineers utilizes state of the art predictive modeling software to conduct thorough mold flow analysis, ensuring top-notch quality and efficient production.

Injection Molding from Prototyping to Production

Our Injection Molding Tooling Capabilities

At F&Q TECH, we excel in creating bespoke injection molds with unparalleled precision and premium materials. Rest assured, we offer competitive rates and swift turnaround times, catering to both small-scale production and large-scale manufacturing needs. Our molds adhere to the most rigorous global benchmarks and are designed for long-lasting performance, providing steadfast reliability and robustness for all your ventures.

|

Mold Class |

Purpose |

Shot Life |

Tolerance |

Lead Time |

|

Class 105 |

Prototype Testing |

Under 500 cycles |

± 0. 02mm |

7-10 days |

|

Class 104 |

Low-volume Production |

Under 100. 000 cycles |

± 0. 02mm |

10-15 days |

|

Class 103 |

Low-volume Production |

Under 500. 000 cycles |

± 0. 02mm |

10-15 days |

|

Class 102 |

Medium-volume Production |

Medium to high production |

± 0. 02mm |

10-15 days |

|

Class 101 |

High-volume Production |

Over 1, 000, 000 cycles |

± 0. 02mm |

10-18 days |

Materials for Injection Mold Tooling

The choice of mold material plays a crucial role in determining the longevity and quality of the injection molded part. F&Q TECH offers a wide range of material grades to suit different needs throughout your product development process. Our team of experts provides valuable guidance to help you select the best mold material for achieving superior dimensional accuracy and aesthetic appeal.

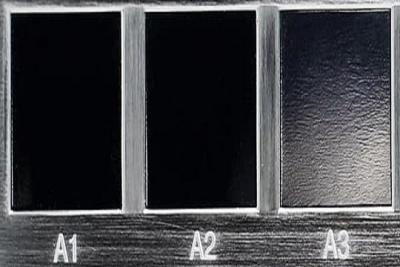

Surface Finishing of Plastic Injection Molds

Our exceptional surface finishes excel in transforming your custom injection molds into remarkable creations. We proudly provide a wide array of finishing solutions that elevate the surface quality of your molds. Moreover, our coatings have the added benefit ofenhancing the mechanical strength and durability of your molds.

|

|

Name |

Description |

|

|

Glossy |

A grade finishes are made using a diamond buffing process and yield shiny and glossy surfaces on injection molded parts. |

|

|

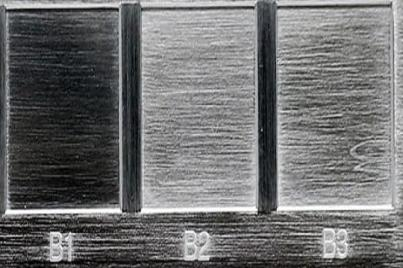

Semi-glossy |

B grade finishes use grit sandpaper to produce parts with a slightly rougher finish than grade A parts. Custom molded plastic parts that undergo B grade finishing have a matte surface texture. |

|

|

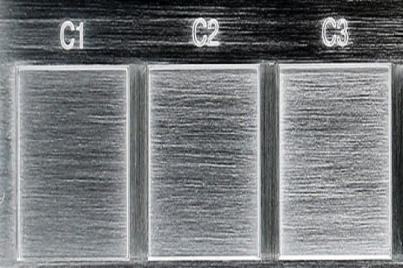

Matte |

C grade finishes use grit sanding stones to produce a rough, uneven surface. Injection plastic parts that undergo C grade finishing have a matte surface texture. |

|

|

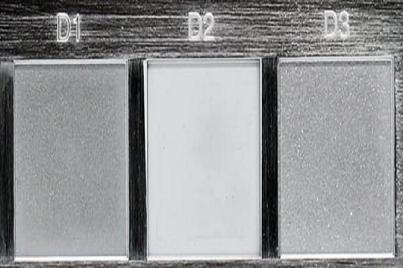

Textured |

D grade finishes use grit and dry glass beads or oxide to produce a very rough textured finish. Depending on the type of material used, products can have a satin or dull finish. |

Why Choose F&Q TECH for Custom Injection Molding Tooling Services

Stringent quality standards guarantee the consistency and excellence of molded parts. Our expert engineering team offers technical assistance at every stage from prototyping to production. F&Q TECH delivers top-notch molds that are dependable and of superior quality.

Work with Us in 4 Simple Steps Only

With decades of manufacturing expertise, F&Q TECH provides top-notch solutions for Injection Mold Tooling and low-volume manufacturing requirements. Our efficient innovation process is broken down into four straightforward and highly effective steps.

Custom Plastic Injection Mold Display

F&Q TECH brings over a decade of expertise in injection molding Tooling to the table. Our state-of-the-art production equipment and skilled engineers enable us to create top-notch high-precision stacked molds, multi-cavity molds, 2k injection molds, and more with exceptional longevity, all at competitive rates.

Injection Mold Tooling of Applications

Injection Mold Tooling of FAQs

The lifespan of injection molding tooling can vary depending on several factors, such as the material being molded, the design of the tooling, the complexity of the part being produced, and the quality of maintenance and care given to the tooling. In general, injection molding tooling can last for thousands to hundreds of thousands of cycles before it needs to be replaced or refurbished. However, this can vary widely depending on the specific circumstances of each production run.

Just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs!