| Standards | Description |

| Maximum Part Size |

1200×1000×500 mm 47.2×39.4×19.7 in |

| Minimum Part Size |

1×1×1 mm 0.039×0.039×0.039 in |

| Part to Part Repeatability |

±0.1 mm ±0.0039 in |

| Mold Cavity Tolerances |

±0.05 mm ±0.002 in. |

| Available Mold Types | Steel and aluminum tooling. Production grade we provide: Under 1000 cycles, under 5000 cycles, under 30,000 cycles, and over 100,000 cycles |

| Machines Available |

Single cavity, multi-cavity, and family molds, 50 to 500 press tonnage |

| Secondary Operations |

Mold texturing, pad printing, laser engraving, threaded inserts and basic assembly. |

| Inspection and Certification Options |

15 business days or less for most orders, 24/7 quotation response |

| Lead Time |

15 business days or less for most orders, 24/7 quotation response |

| Mold Class | Purpose | Shot Life | Tolerance | Lead Time |

| Class 105 | Prototype Testing | Under 500 cycles |

± 0.02mm |

7-10 days |

| Class 104 | Low-volume Production | Under 100.000 cycles | ± 0.02mm | 10-15 days |

| Class 103 | Low-volume Production | Under 500.000 cycles | ± 0.02mm | 10-15 days |

| Class 102 | Medium-volume Production | Medium to high production | ± 0.02mm | 10-15 days |

| Class 101 | High-volume Production | Over 1,000,000 cycles | ± 0.02mm | 10-18 days |

| Tool Steel: | P20, H13, S7, NAK80, S136, S136H, 718, 718H, 738 |

| Stainless Steel: | 420, NAK80, S136, 316L, 316, 301, 303, 304 |

| Aluminum: | 6061, 5052, 7075 |

| UV | absorbers | Colorants |

| Flame | retardants | Glass fibers |

| Plasticizers |

Injection molding is a comprehensive process that encompasses injection mold tooling, plastic injection molding, and more. The surface treatment of the mold is typically finalized throughout production. Following the completion of the injection molding, we will conduct specific surface treatments on the finished product to meet your specifications.

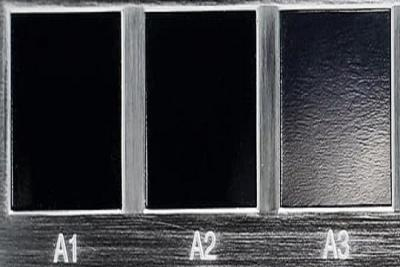

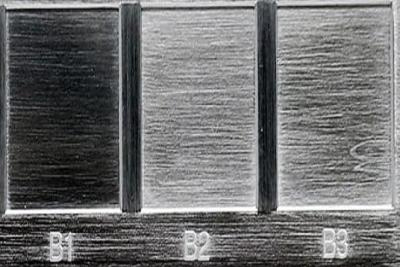

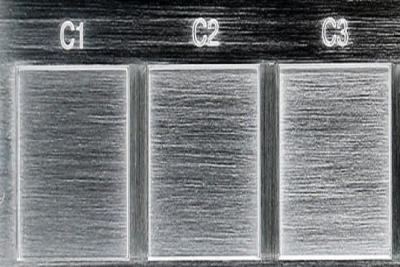

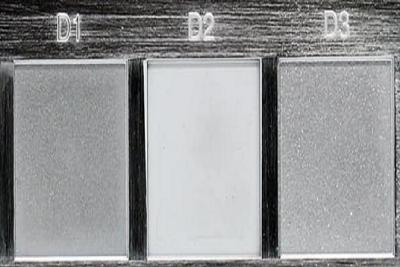

| Name | Description | |

|

Glossy | A grade finishes are made using a diamond buffing process and yield shiny and glossy surfaces on injection molded parts. |

|

Semi-glossy | B grade finishes use grit sandpaper to produce parts with a slightly rougher finish than grade A parts. Custom molded plastic parts that undergo B grade finishing have a matte surface texture. |

|

Matte | C grade finishes use grit sanding stones to produce a rough, uneven surface. Injection plastic parts that undergo C grade finishing have a matte surface texture. |

|

Textured | D grade finishes use grit and dry glass beads or oxide to produce a very rough textured finish. Depending on the type of material used, products can have a satin or dull finish. |

Just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs!