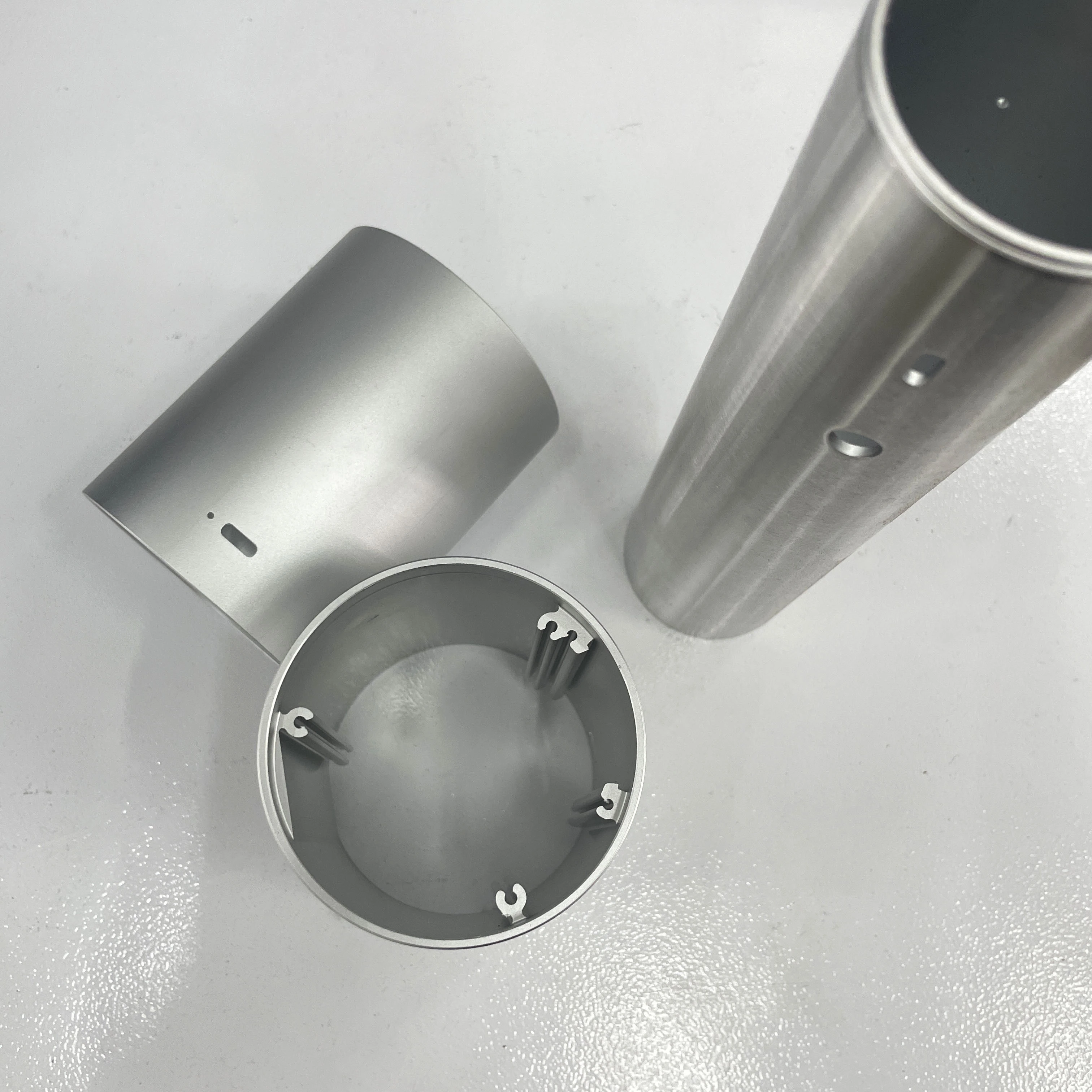

Custom Sheet Metal Fabrication Service: Stainless Steel Tube Welding, Aluminum Laser Cutting Parts

Product Description

▶ 1. Unmatched Fabrication Expertise

We bring years of experience in sheet metal fabrication to every project. Our capabilities include:

● Stainless Steel Tube Welding: Utilizing advanced welding techniques, we ensure strong, seamless joints for stainless steel tubes. This not only enhances the structural integrity of your metal enclosures but also guarantees resistance to corrosion and wear, making them ideal for long - term use in various environments.

● Aluminum Laser Cutting: Leveraging state-of-the-art laser cutting technology, we achieve intricate and precise cuts on aluminum sheets. This allows for the creation of complex shapes and detailed designs, perfect for crafting the sleek and sophisticated metal shells required for audio and other small household appliances.

▶ 2. Tailored for Small Household Appliances

Our metal enclosures are specifically designed for applications in small household appliances, with a focus on audio devices:

● Perfect Fit and Function: Each enclosure is custom - made to match the exact specifications of your appliance, ensuring a perfect fit that integrates seamlessly with the device's internal components.

● Aesthetic Appeal: The smooth surfaces and precise cuts of our aluminum parts, combined with the robust look of welded stainless steel tubes, add a touch of elegance and professionalism to your products, enhancing their market appeal.

▶ 3. Quality You Can Rely On

Quality is at the core of our fabrication process:

● Material Selection: We use only high - grade stainless steel and aluminum, sourced from trusted suppliers, to ensure the durability and performance of our products.

● Rigorous Inspection: Every fabricated part undergoes strict quality checks at every stage of production, from raw material inspection to the final product, to ensure it meets our high standards and your requirements.

▶ 4. Why Choose Our Service?

● Customization: We work closely with you to understand your specific design and functional needs, delivering fully customized solutions.

● Efficiency: Our advanced equipment and streamlined production processes enable us to deliver your orders in a timely manner without compromising on quality.

● Cost - Effectiveness: By optimizing our fabrication processes and leveraging economies of scale, we offer competitive pricing without sacrificing the quality of our products.

Whether you need a single prototype or large - scale production, our custom sheet metal fabrication service is here to bring your small household appliance designs to life with precision and quality.

FAQ

Just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs!