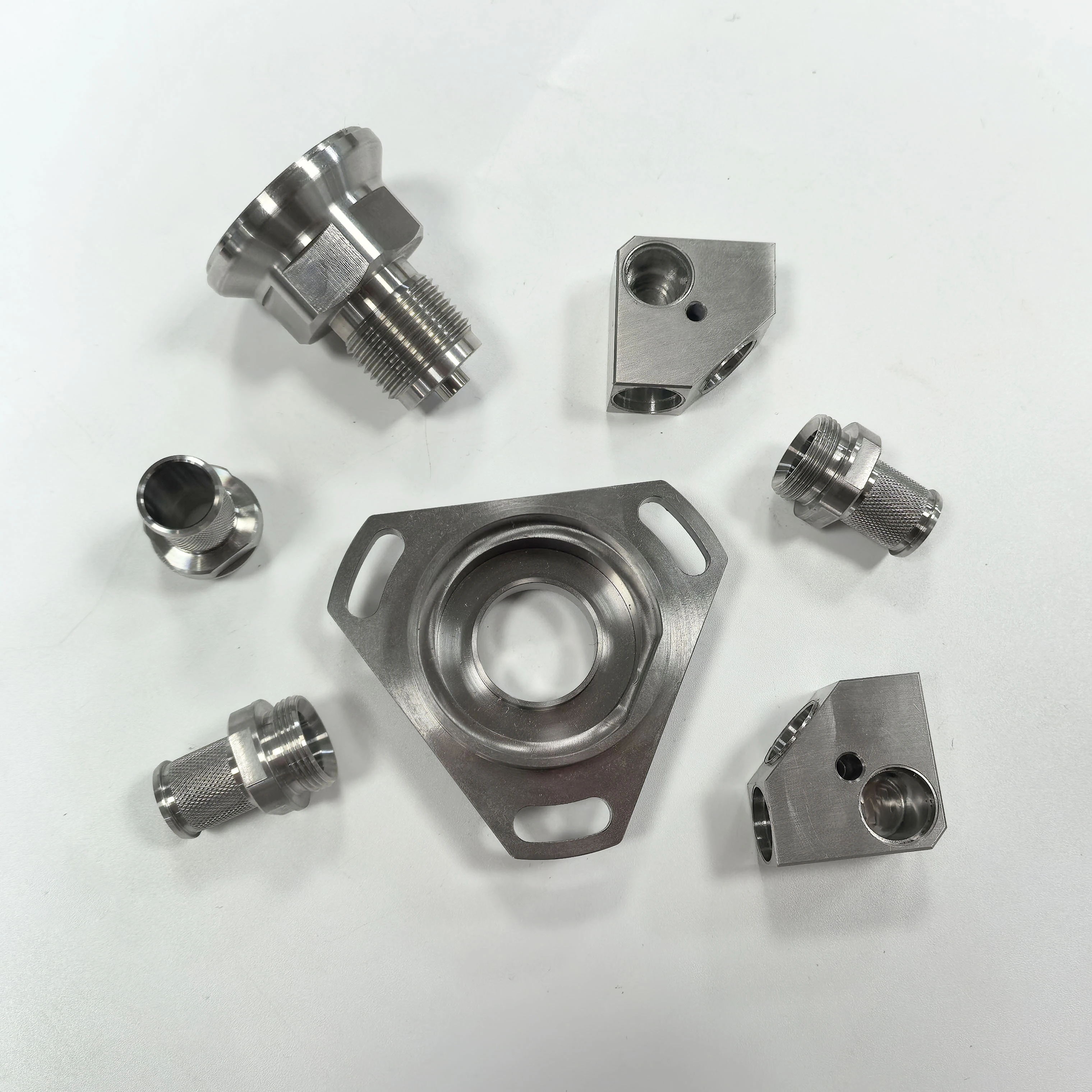

Custom High Precision Manufacturing Aerospace CNC Machined Components

Product Description

▶ In the aerospace industry, balancing lightweighting with high strength is a core design challenge. Aluminum precision components, with their excellent strength-to-weight ratio, corrosion resistance, and processability, are an ideal choice for many critical parts. Our aluminum CNC machining products, specifically designed for the aerospace industry, meet the industry's stringent component requirements, from material selection to precision machining.

Core Advantages:

▶ 1.Specialized Machining Technology for Aerospace-Grade Aluminum

● Using aviation-grade aluminum (such as 6061-T6 and 7075-T73), these materials offer both high strength and lightweight properties (with a density only one-third that of steel), significantly reducing the overall weight of spacecraft and aircraft, while improving fuel efficiency. Customized CNC machining parameters allow for precise control of cutting speeds and feed rates, minimizing surface finish issues caused by aluminum's high plasticity and tool sticking, ensuring a surface finish of Ra0.8μm or less.

▶ 2.High Precision and Structural Stability

● Utilizing a five-axis machining center and advanced cooling system, thermal deformation during aluminum processing is effectively controlled, maintaining part tolerances within ±0.002mm. This is a perfect match for the high-precision assembly requirements of aerospace equipment. Whether it's complex, custom-shaped structures (such as satellite antenna brackets and airborne equipment frames) or connectors with minute holes, dimensional accuracy and structural stability are guaranteed.

▶ 3.Full Compliance and Quality Traceability

● The production process strictly adheres to the AS9100 aerospace quality management system certification. All aluminum used is traceable to the original manufacturer and comes with complete material certification. Every product undergoes comprehensive testing using high-precision equipment such as coordinate measuring machines, and a detailed test report covering key indicators such as dimensional accuracy and mechanical properties is provided to meet the stringent regulatory requirements of the aerospace industry.

▶ 4.Customized Solutions to Meet Diverse Needs

● Starting with initial DFM (Design for Manufacturability) analysis, our team of engineers provides expert advice on the specific characteristics of aluminum parts, such as optimizing the structure to reduce processing stress and selecting appropriate surface treatments (such as anodizing and passivation) to enhance corrosion resistance. We support a full service process from single-piece prototypes to mass production, quickly responding to customer customization needs and shortening product development cycles.

We deeply understand the challenges of aluminum parts in aerospace applications. Through sophisticated CNC machining techniques, we maximize the performance advantages of aluminum and provide reliable and cost-effective component solutions for your projects.

Consult us now to receive customized aluminum part processing solutions tailored to your needs!

FAQ

Just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs!