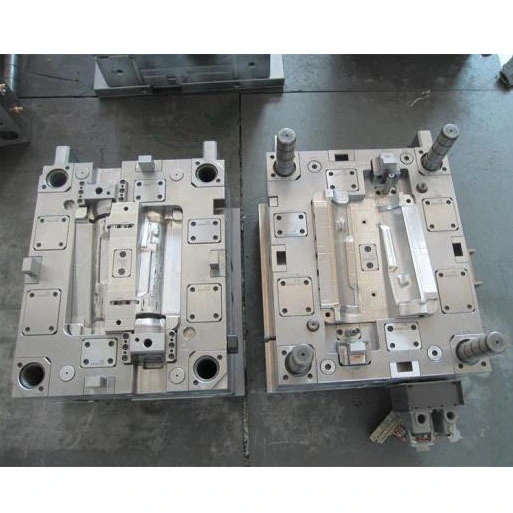

Custom Automobile Dashboard Cover Mould

Our carefully crafted automotive plastic instrument panel cover injection mold is the key to ensuring the quality of automotive interiors. The core advantage of this mold lies in its ultra-high manufacturing precision. From the dimensional tolerance of the mold cavity to the surface finish, everything is strictly controlled. The cavity dimensional error can be controlled within ±0.01mm, ensuring that the edges of the produced instrument panel covers fit tightly, without burrs or warping, and perfectly matching the assembly requirements of automotive interiors. The mold's guide mechanism uses high-precision guide pins and guide sleeves with extremely small clearances to ensure smooth and accurate mold opening and closing movements, avoid product defects caused by mold shaking, and ensure that each molded instrument panel cover has consistent high quality.

5.0

like

Surface treatment:

None

Service:

Injection Mould

Material:

Mold Steel

Drawing Format:

STP. STEP . IGS . PRT . X_T, PDF

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

Product details

As leaders in custom injection molding, we're not just mold manufacturers; we're your complete molding solution experts!Custom made all kinds plastic injection mold, and custom all kinds plastic injection molding production, and also with surface treatment(paint, print, water trans-print, welding, assemble) .

image005 (2)

image006 (2)

image001 (2)

Material selection

The materials of our products include PC/ABS /PMMA /PA6 PA66 PBT POM AS ASA PPS PPA

Product description

Surface treatment

We can do a variety of surface treatments, such as Polishing, Texture, Paning etc.

Mould Material

There are also many options for mold materials: 45#/ 50#/ P20/ 718/ 12343/ NAK80/S136

Mold design

We have a professional team in mold design

FAQ

1

Q: Which industries are your products used in ?

A: Our products are used in motor heat dissipation, oven bakeware, automation equipment, motorcycles, auto parts, bearing seats, lighting tools, etc.

2

Q: What's the production time for new molds and mass production?

A: 10-20 days to make the new moulds, mass production takes around 15 days, can process urgently if need

3

Q: Can you send me samples ?

A: Yes, Samples are for free, and freight is on your side.

4

Q: How long is the lifetime ?

A: Powder coating for 18-20 years outdoor.

5

Q: What is the payment terms ?

A: T/T: 30% deposit, the balance will be paid before delivery;

L/C: The balance irrevocable L/C at sight.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Inquiry me now, get the price list.

Just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs!

Related Products

no data

Quick Links

Service

Newsletter

Subscribe to our Newsletter for the latest news, updates and offers.

F&Q TECH is a registered trademark of Star Rapid., Ltd© 2017.

All Rights Reserved.

ISO 13485:2016, 9001:2015, 14001:2015, 45001:2018 Certified.

ISO Certification ID: 9105072657