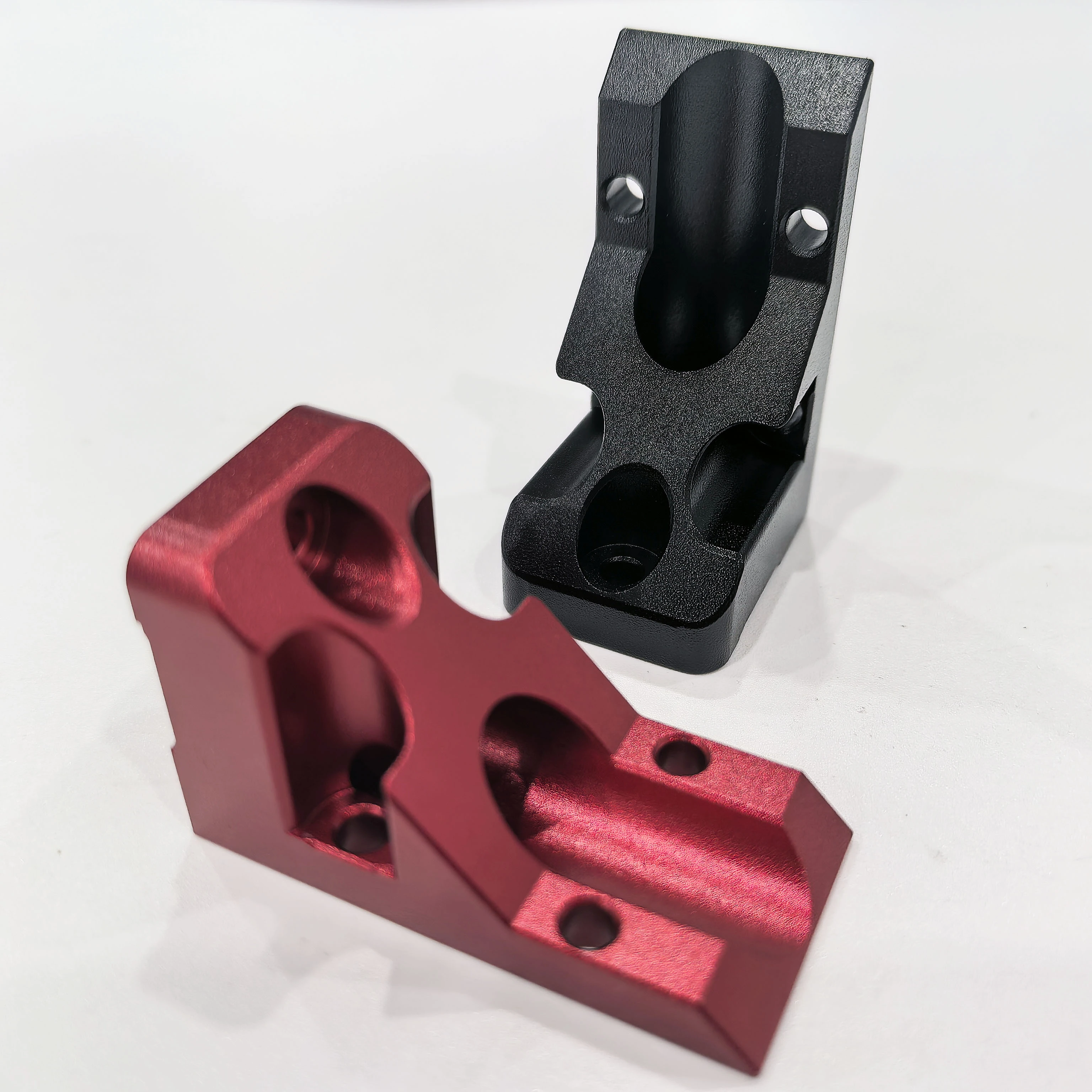

Precision CNC Parts with Durable Anodizing (Black/Red) and Sandblasted Surface

Product Overview

▶ Our custom CNC machining services are designed for industries requiring the highest precision and exceptional surface quality. We utilize advanced CNC machine tools to manufacture high-quality materials (such as aluminum alloy and stainless steel). We then apply specialized anodizing (available in black or red) and sandblasting to deliver metal parts that are not only dimensionally accurate but also aesthetically pleasing and durable.

▶ Core Advantages and Process Details:

● Ultra-High Precision Guarantee: Leveraging advanced CNC milling and turning technologies, we strictly adhere to your drawings to ensure the precise reproduction of each part's complex geometries and fine tolerances (down to ±0.01mm).

● Dual Surface Treatment: Each part undergoes both sandblasting and anodizing.

● Sandblasting: Effectively eliminates surface imperfections, creating a uniform, fine matte finish that provides the perfect base for anodizing.

● Anodizing: Significantly improves surface hardness, wear resistance, and corrosion resistance, while creating a stable color coating. We offer classic black and vibrant red options to meet your product logo and aesthetic needs.

● Excellent Durability: The anodized surface is extremely hard, scratch-resistant, and corrosion-resistant, ensuring it withstands harsh environments and extends product life.

● Comprehensive material selection: We can process a variety of metal materials, including but not limited to 6061 aluminum alloy, 304/316 stainless steel, brass, etc., to meet your different needs in terms of strength, weight and cost.

▶ Applications:

● Aerospace components

● Automotive performance parts

● High-end consumer electronics housings

● Robotics and automation mechanical components

● Precision medical device components

● Photographic equipment and optical instruments

▶ Our customized service process:

● Submit Drawings: Provide your 3D CAD drawings (e.g., STP. STEP . IGS . PRT . X_T,) and 2D drawings (e.g., PDF) along with your technical requirements.

● Get a Quote: Our team of engineers will quickly review your requirements and provide a competitive quote and delivery schedule.

● Confirm Production: Once your order is confirmed, we'll immediately schedule production and implement strict quality control.

● Quality Inspection and Shipping: Each part undergoes rigorous quality inspection to ensure compliance, is properly packaged, and shipped on time.

Get Your Custom Quote Today

Ready to enhance your battery system’s performance with our high-conductivity Copper Nickel Plated Flexible Busbar? Contact us now to discuss your custom requirements:

● Email: lyy@fsqj-tech.com

● Phone: +86 136 1605 5490

● Contact Form: Fill out our online form with your specifications, and we’ll send a detailed quote within 24 hours.

We look forward to working with you to provide reliable solutions for your customized needs.

Just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs!